Mosquito Control Tips & Educational Resources

We know how difficult it can be to manage mosquitoes. Effective mosquito management requires science-backed solutions, data collection, and knowledge from entomologists, biologists, environmental health specialists, and vector management experts. That’s why we produce educational articles to help you understand the fundamentals of mosquito management so that you can make informed decisions regarding your community’s mosquito management program.

This year’s educational blogs covered various topics including emergency response planning, understanding action thresholds, personal protection tips for citizens, and more. Below are the top articles you found the most interesting and informative in 2023!

Aerial Mosquito Spraying and How We Make It Safe

Mosquitoes pose one of the most significant threats to public health which is why they require careful monitoring and management to prevent the spread of dangerous diseases like West Nile virus, Eastern Equine Encephalitis, and Zika. When mosquito populations reach an unacceptable level or a disease outbreak occurs, aerial mosquito spraying is often required. Discover how aerial mosquito spraying fits into an Integrated Mosquito Management program and how we make our application safe and effective.

VDCI’s Guide to Helping You Educate Community Members About Mosquitoes

One of the most important aspects of mosquito management is public education. When citizens understand how mosquito-borne diseases spread, the habitats in which mosquitoes breed, and ways they can protect themselves from bites, they can help limit the dangerous impact of mosquitoes. In addition, when community members are educated on their local mosquito control efforts, the program has a greater chance of long-term success. Discover how to strengthen your mosquito management program and keep your citizens safe with this public education guide.

Mosquito Natural Disaster Response: Are You Prepared for the Big Storm?

Severe weather can be devastating to our communities, bringing heavy rain and flooding, damaging infrastructure, displacing people from their homes, and creating conditions that promote overwhelming mosquito populations. Luckily, government leaders can prepare for abundant mosquito populations by building an emergency response plan. Discover how to build a contingency plan and explore the benefits of partnering with a professional mosquito management company that can help you navigate post-storm mosquito problems.

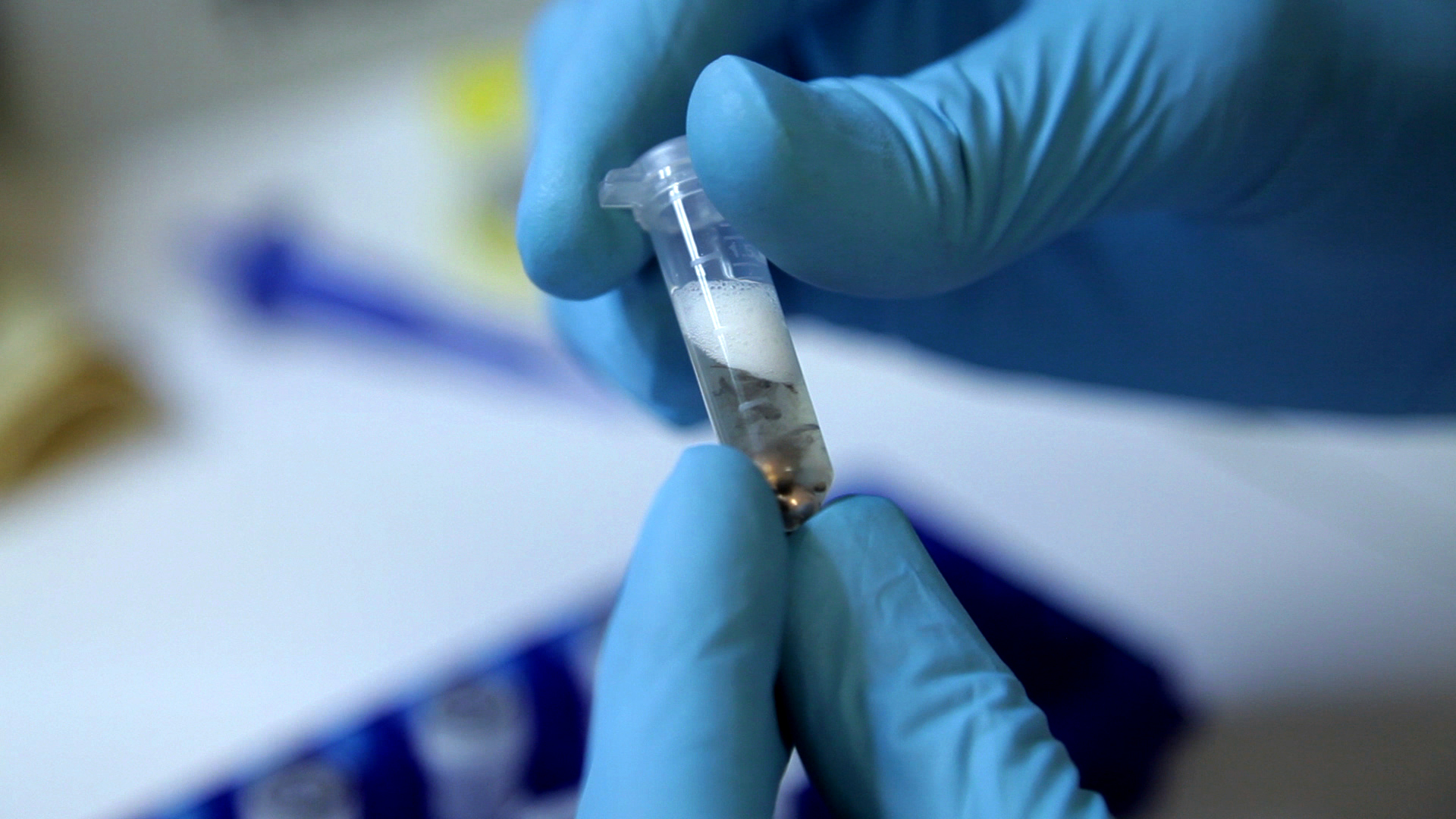

3 Mosquito Surveillance Techniques Professionals Utilize

Surveillance is one of the most important aspects of an Integrated Mosquito Management program. When you have a deep understanding of the local mosquito population, you can implement the appropriate control measures in the right place, at the right time. Collecting and analyzing data should occur during mosquitoes’ various life stages: egg, larval, pupae, and adult. Learn about the three types of surveillance techniques and how professionals utilize the data to optimize mosquito management strategies.

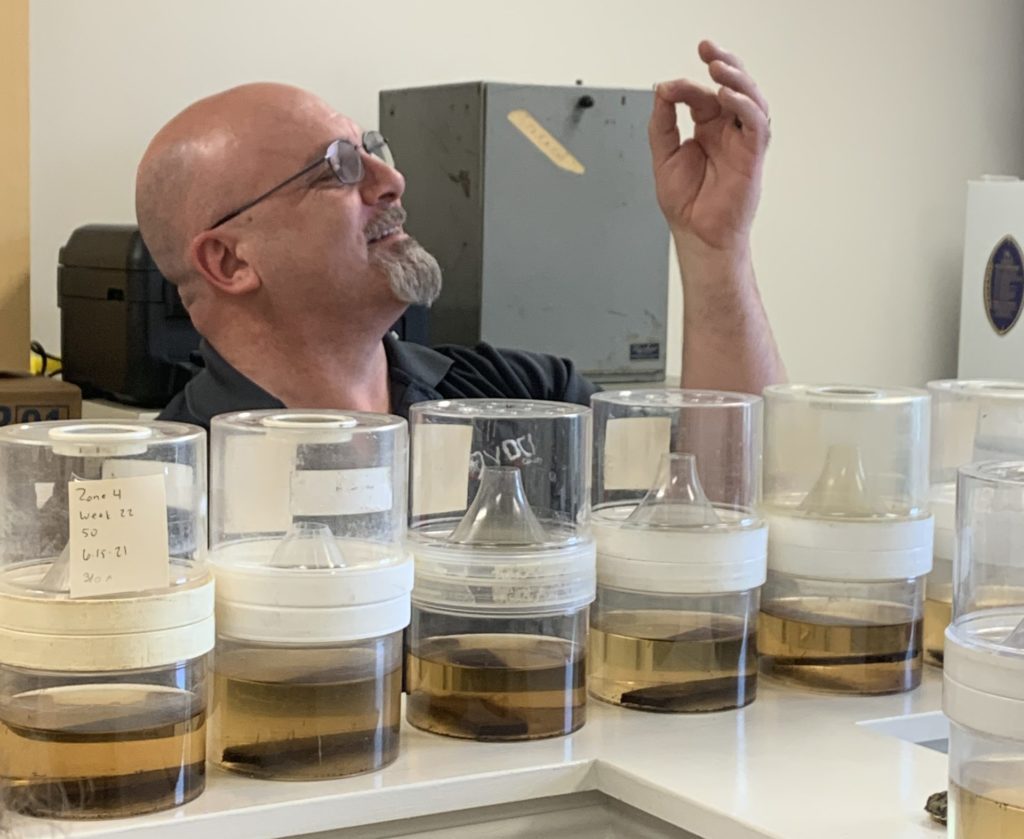

Deep Dive Into A Mosquito Laboratory

Mosquito laboratories play a critical role in every step of the management process, from building Integrated Mosquito Management (IMM) programs and emergency response plans to keeping the public informed about mosquito activity. We believe that everyone deserves peace of mind while enjoying the outdoors, which is why we use laboratory testing and data collection to drive safe, efficient, and environmentally friendly IMM programs. Discover what goes on behind the scenes in a professional mosquito laboratory.

Create Safe, Enjoying Outdoor Spaces for Citizens

Protecting public health is our top mission at VDCI. We want to help government leaders like you create effective and safe mosquito management programs that keep nuisance mosquito populations under control while also protecting citizens from the potential transmission of dangerous diseases. Are you ready to build an Integrated Mosquito Management program? Contact us today to get started.

What to explore our other educational blogs? Click here.

Contact Us to Build Your Mosquito Management Program:

Since 1992, Vector Disease Control International (VDCI) has taken pride in providing municipalities, mosquito abatement districts, industrial sites, planned communities, homeowners associations, and golf courses with the tools they need to run effective mosquito control programs. We are determined to protect the public health of the communities in which we operate. Our mosquito control professionals have over 100 years of combined experience in the field of public health, specifically vector disease control. We strive to provide the most effective and scientifically sound mosquito surveillance and control programs possible based on an Integrated Mosquito Management approach recommended by the American Mosquito Control Association (AMCA) and Centers for Disease Control and Prevention (CDC). VDCI is the only company in the country that can manage all aspects of an integrated mosquito management program, from surveillance to disease testing to aerial application in emergency situations.

Since 1992, Vector Disease Control International (VDCI) has taken pride in providing municipalities, mosquito abatement districts, industrial sites, planned communities, homeowners associations, and golf courses with the tools they need to run effective mosquito control programs. We are determined to protect the public health of the communities in which we operate. Our mosquito control professionals have over 100 years of combined experience in the field of public health, specifically vector disease control. We strive to provide the most effective and scientifically sound mosquito surveillance and control programs possible based on an Integrated Mosquito Management approach recommended by the American Mosquito Control Association (AMCA) and Centers for Disease Control and Prevention (CDC). VDCI is the only company in the country that can manage all aspects of an integrated mosquito management program, from surveillance to disease testing to aerial application in emergency situations.

Whether larviciding or adulticiding, timing in Aerial Mosquito Control is an extremely critical component. Knowing the amount of time that is required to go through all the protocols, preflight the aircraft, and be able to hit the “spray on” switch at the exact specified time, to ensure a successful mission, can sometimes present its challenges – but must be accomplished.

Whether larviciding or adulticiding, timing in Aerial Mosquito Control is an extremely critical component. Knowing the amount of time that is required to go through all the protocols, preflight the aircraft, and be able to hit the “spray on” switch at the exact specified time, to ensure a successful mission, can sometimes present its challenges – but must be accomplished.